The content of the article

Porcelain tile - durable and at the same time fragile material. It is resistant to temperature changes and, unlike tile, it has high wear resistance. The material has refractory properties and low water absorption. The porcelain stoneware consists of compressed clay mixed with solid minerals, so it does not crumble and practically does not scratch. To cut such a tile is more difficult than a tile, but it is possible. The main thing is to choose the right way.

Classic method

Lining material, the thickness of which does not exceed 8-10 mm, is divided into parts using a glass cutter. A tool with a diamond tip draws straight lines. Cut patterns or complex shapes will not work:

- The tile is laid on the floor or table.

- Hold hands, you can step foot. The main thing is that the workpiece is securely fixed and does not move during operation.

- In addition to the glass cutter, you will need an iron ruler or a building level.

- Pencil draw on the outside of the cladding material line cut. Apply level to it.

- Carry out over the ceramic granite surface with a diamond tip.

- The tool is pressed in so that the blade penetrates the inner layer of the tile.

- The force is reduced when the glass cutter reaches the edge. If too much pressure is placed on this area of facing material, chips will appear.

If the cut is deep enough, the tile without serious damage will split into two parts. It is possible to separate the facing material with the hands, but this method is more dangerous. Small pieces of porcelain tile scatter in different directions, getting into the eyes.People who decide to break the facing material with their hands are advised to wear glasses and thick gloves.

The rough edges of the tiles are treated with a grinding net or wheel. Sandpaper with large or medium abrasive particles will also be suitable.

Beginners do not always manage to split porcelain stoneware into pieces without serious damage. If you decided to process the facing material with a glass cutter, you need to buy a tile with a margin and a few tools. The diamond tip is quickly blunted when in contact with pressed clay.

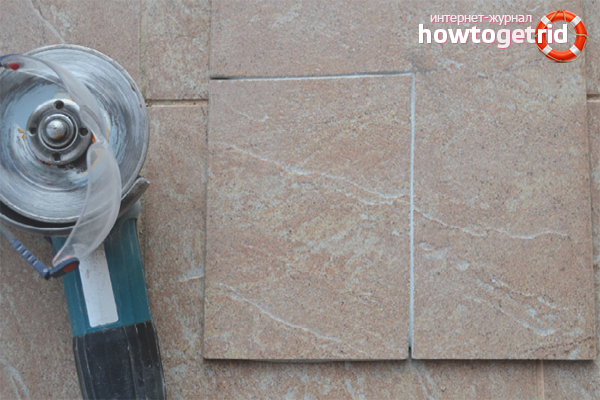

Electrical devices

Ceramic granite tile grinder cut. A diamond-coated disk is put on the electric tool. The nozzle is integral, without teeth and holes, designed for dry cutting.

Tile markup marker or chalk. Lines draw on the outside. Facing material must be fixed on a table or other stable base. In order not to spoil the tile, 2-3 mm recede from the line. The grinder is turned on and carried out once on a porcelain stoneware surface. At the edges of the disc speed should be slowed down, so as not to appear chipped. Re-pass on the tile can not.If it was not possible to cut the billet the first time, it should be gently broken with your hands or feet.

Grinder grind uneven edges. The dry cutting disc is replaced with a stone variant. Turn on the electric tool at minimum speed and handle tile cut.

Glazed cladding material is cut in another way. The Bulgarian leaves too much chips and damage on the porcelain stoneware surface. After processing, the tile has to be thrown away, because even grinding machines cannot eliminate defects.

The grinder is made not only straight, but also curvilinear cuts. Include the minimum speed and gently spend on the previously scheduled lines. Decorate the ceramic granite surface with patterns or complex patterns will not work. The Bulgarian is able to cut a circle, a triangle or another geometric shape with a minimum of details. The disk is tilted at an angle of 45–60 degrees to the surface. After cutting, the edges of the porcelain are ground.

The method is rather dusty and noisy, therefore it is recommended to work with facing material on the street or in a ventilated room.Wear a gauze bandage or respirator, goggles and boots with thick soles. Hold the tool tightly while working.

Tile decor

Complex patterns on the porcelain stoneware surface are cut with an electric jigsaw. The tool is equipped with diamond wire, which is able to cut even such durable facing material.

First, on the outside of the tile draw patterns. Use a pencil or chalk, which is easily washed. The workpiece is fixed on the table. The surface is moistened with water, retreating from the edge of at least 8 mm. The nozzle moves slowly and gradually. After each small curl, the instrument is turned off and the crumb is brushed away from the porcelain stoneware in order to see the pattern more clearly. The material is periodically sprayed with water from a spray bottle. Moisture will facilitate the sliding of the diamond wire and protect the tile from scratches and large chips.

It is possible to decorate porcelain tile with difficult patterns by means of a usual drill. For thick blanks take drills with a diameter of 8 and 12 mm. Holes are made in the thin tile, the size of which does not exceed 4 and 6 mm in order to prevent the appearance of chips.

Pencils on the front surface draw the planned patterns. Carefully guide the contour and mark the dots where the holes should be. Recommend to observe the distance from 5 to 10 mm, a little less. Be sure to retreat from the edges of at least 0.8 cm.

The first stage is drilling to incomplete depth. Drill equip nozzle with a diameter of 8 or 4 mm, depending on the thickness of the material. Then use a larger drill bit, which is inserted into the finished grooves. Slowly press on the drill, trying to get the tool into the tile to the very foundation.

Porcelain stoneware pieces are separated from the tile with dowels. Nails are inserted into the drilled hole and lightly hit them with a hammer until a nickle appears on the treated surface. Sometimes the remnants of pressed clay are cleaned with a chisel, and then polished edges of the pattern with coarse sandpaper.

The fret saw and drill will cope with a small amount of porcelain stoneware. Only specialists who have hydroabrasive installations can cover 100 or more tiles. Facing material is treated with a stream of water containing particles of sand or other solid material.It cuts porcelain stoneware, like a plain sheet of paper, leaving no chipping or scratching. The edges of the patterns after professional processing do not need to be sanded. They are smooth and smooth.

Straight cut

The tile can be divided into 2–4 large pieces by a circular saw. Porcelain tiles are laid out before work. Serrated nozzle replaced with a solid disc without holes, preferably with a diamond coating.

Tile hold with two hands and slowly move to the included tool. The circular saw works more slowly than the grinder, but thanks to the adaptation, the cuts are smooth and smooth and do not need to be polished.

In the building stores sold professional tile cutters. They are electrical and mechanical. The first type is similar to the grinder. It has a round disc with a diamond coating, which easily cuts the tile into pieces. Sold complete with a bed, which is attached porcelain. Electric tile cutters are dry and wet. The latter are equipped with a water tank that moisturizes the instrument during operation. The liquid protects the equipment from overheating. An additional advantage of a wet instrument is the absence of dust.

The mechanical tile cutter is similar to a bed equipped with clamps and levers for fixing and bending porcelain stoneware. The tool has a cutter, which will have to be periodically changed. Mechanical tile cutters are not intended for decorating tiles with patterns. They only make straight cuts. The advantage of such a device is the absence of loud sounds and dust.

Tile cutters are bought by people who plan to continue to engage in the repair and laying of ceramic-granite tiles. They are quite expensive, so it's easier to use a grinder or a circular saw.

It is no more difficult to work with porcelain stoneware than with tile, if you have the right tools at hand. The circular saw and the Bulgarian can cut a strong and fragile material. With a thin tile handle and glass cutter. And for ornate patterns have a drill and a jigsaw with a wire nozzle.

Video: how to cut porcelain tiles

To send